The perfect stencil for earrings - a tutorial for you!

Use the Bails stencils to create beautiful earrings in this free tutorial

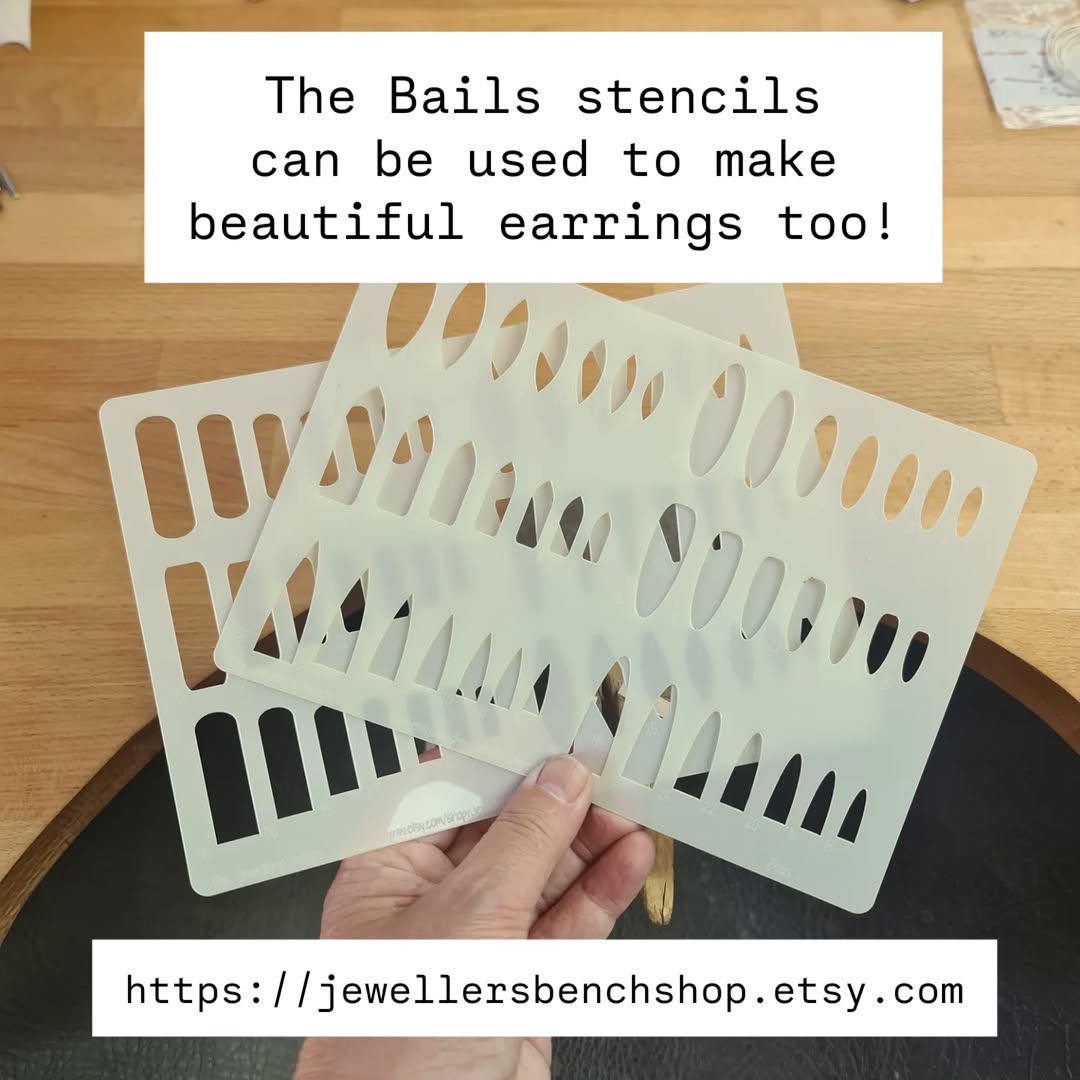

The Bails stencils can be used to make beautiful earrings.... so here's just one possible idea (with a few variations!)

You will need:

Materials:

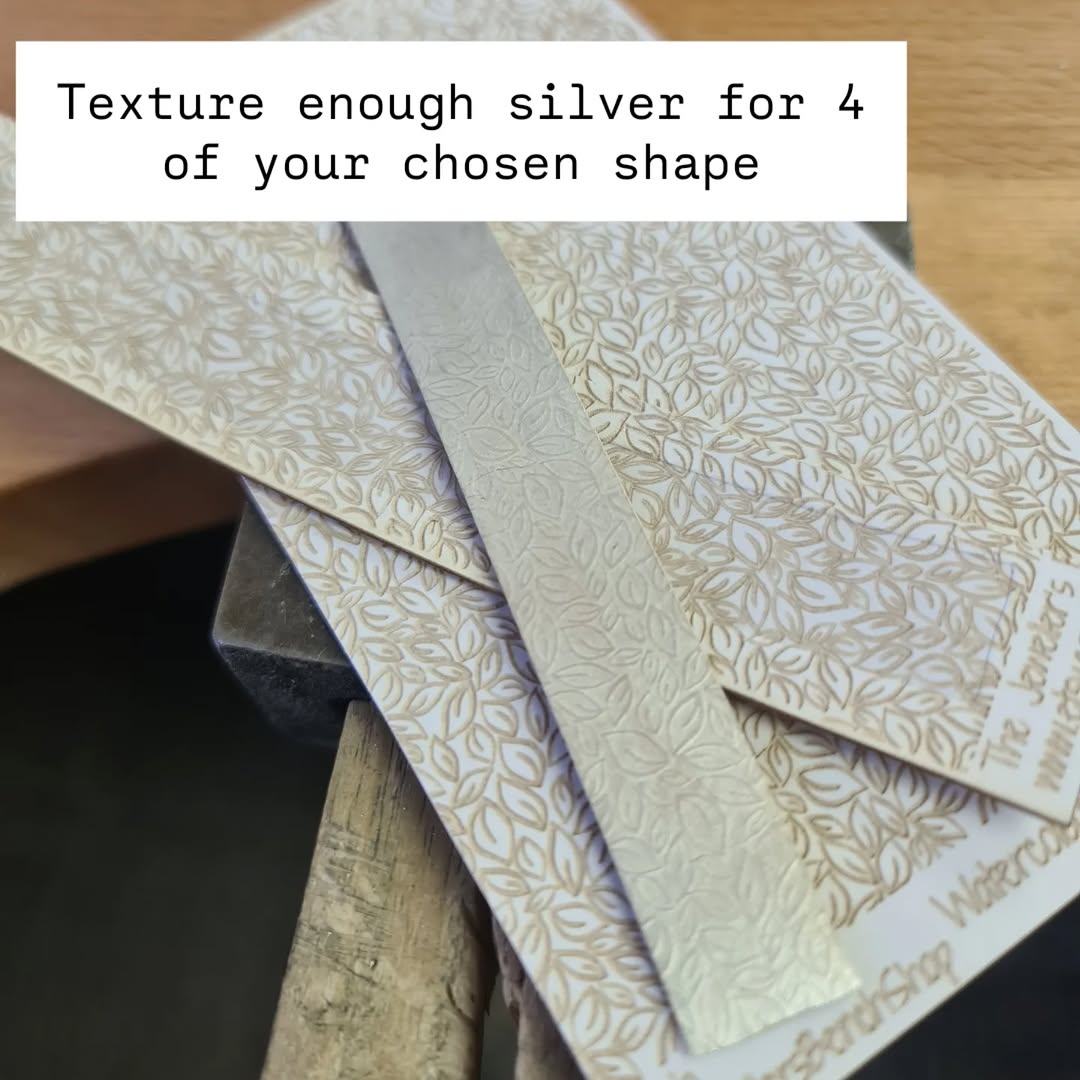

- Sterling silver large enough for 4 of your chosen shape. A thickness of 0.6mm-0.7mm is ideal

- 0.8mm (20 gauge) wire for the earwires. I used two 5.5cm lengths

- A rolling mill texture sheet (I used the Watercolour Leaves 2 Medium texture). Alternatively, texture your silver with a hammer.

- Optional: stone or halfdrilled pearl for the bottom of the earring, plus the materials to set the stone/pearl in.

Equipment:

- Soldering Kit

- Jeweller's saw and bench peg

- Flat file and emery paper

- Bails 1 or Bails 2 stencil (depending on the shape you want!) and sharpie

- Nylon jaw pliers, flat nosed pliers, wire cutters

- Planishing (rounded) hammer and bench block

- Doming block and wooden punch

- Rolling Mill (unless you choose a hammered

And here's how to do it!

|  |  |

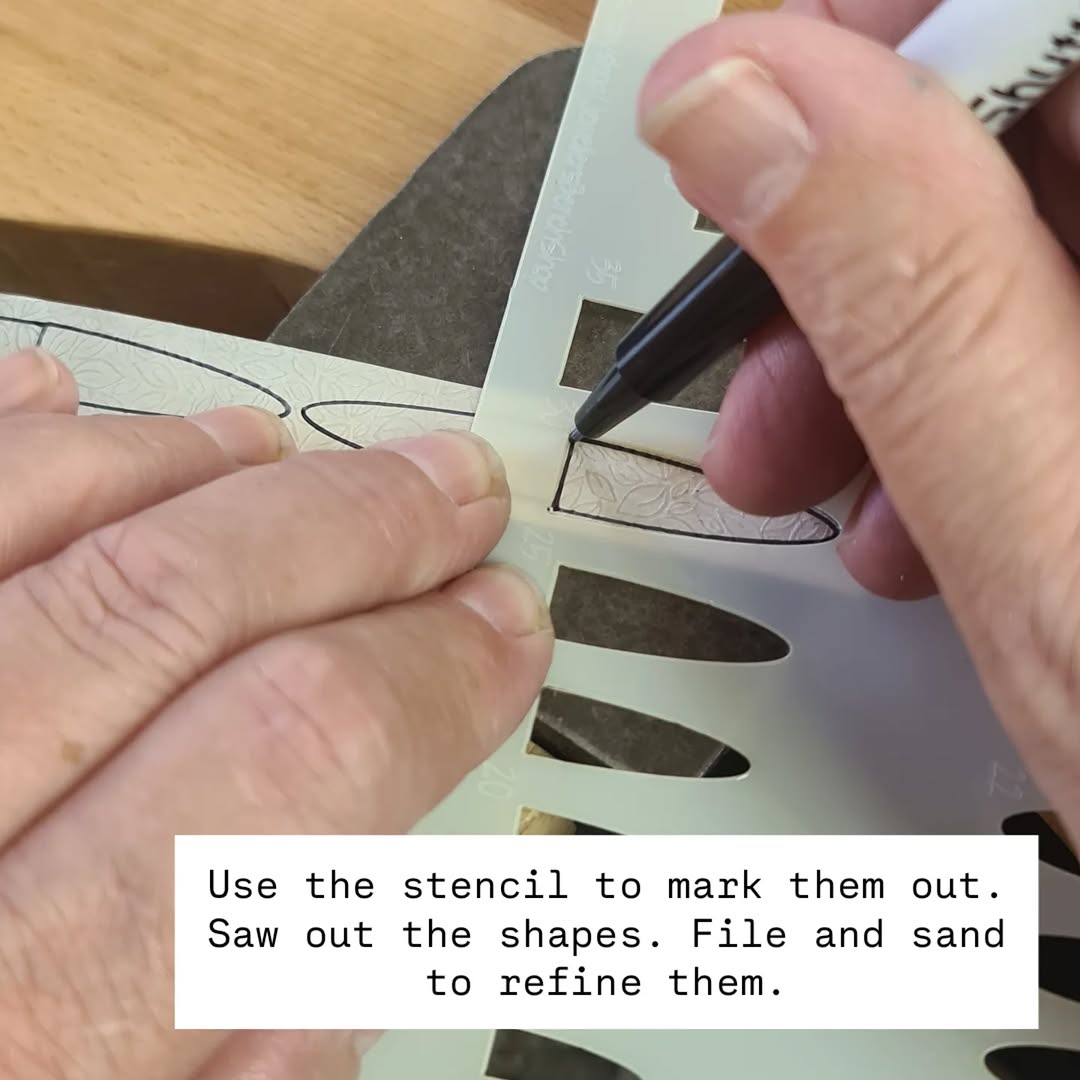

1. Anneal the silver and texture it with the texture sheet and rolling mill. | 2. Choose a shape from the Bails

stencil and mark four of them on the silver sheet. Saw each shape out. File and sand the edges to refine the shapes

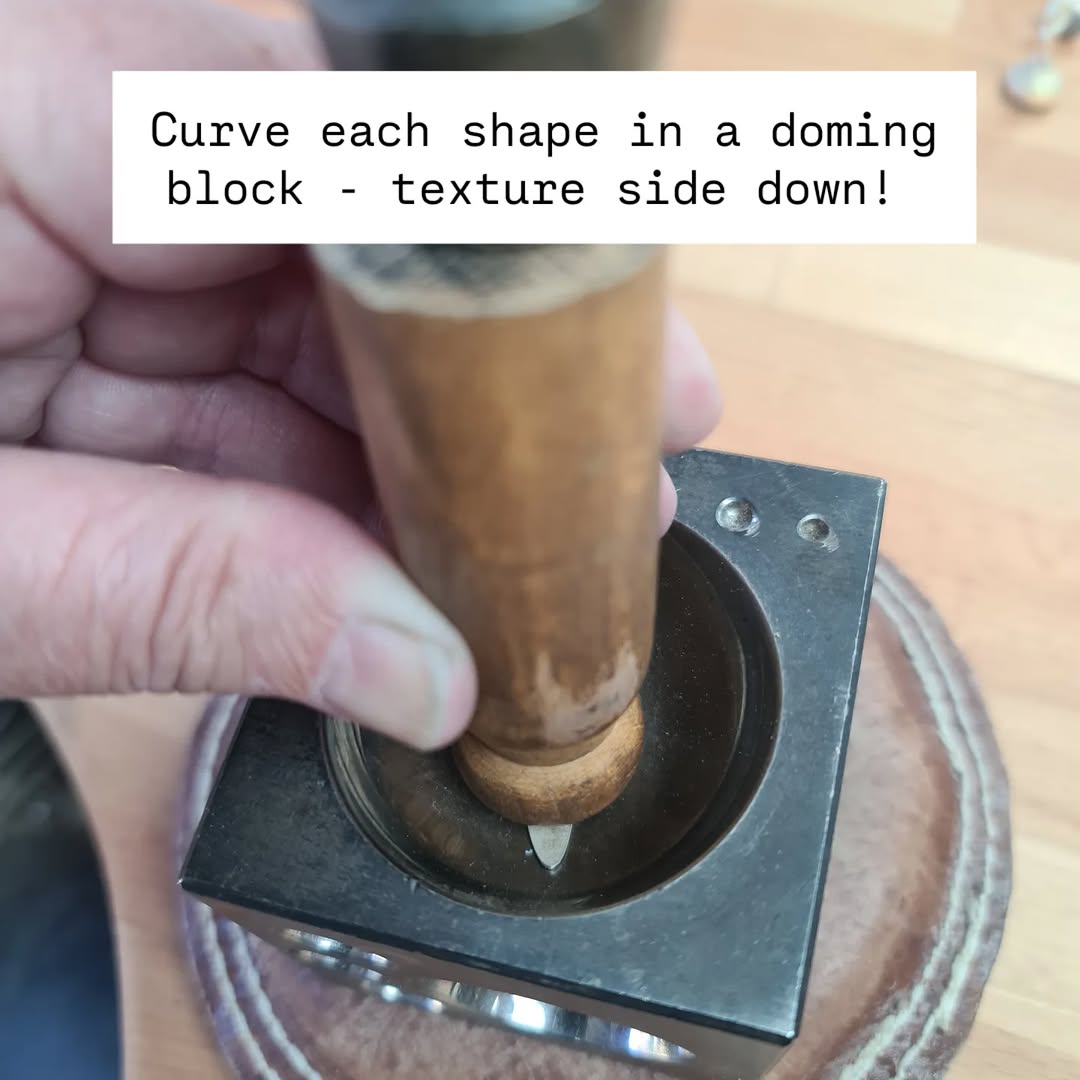

and make them lovely and smooth. | 3. Add a curve to each shape with

the texture on the outside of the curve. I used the largest dish on my doming block, but shaped nylon pliers or even bending the silver around a

suitable curve will do the trick.

Use a wooden punch with the doming block to protect the texture. |

|  |  |

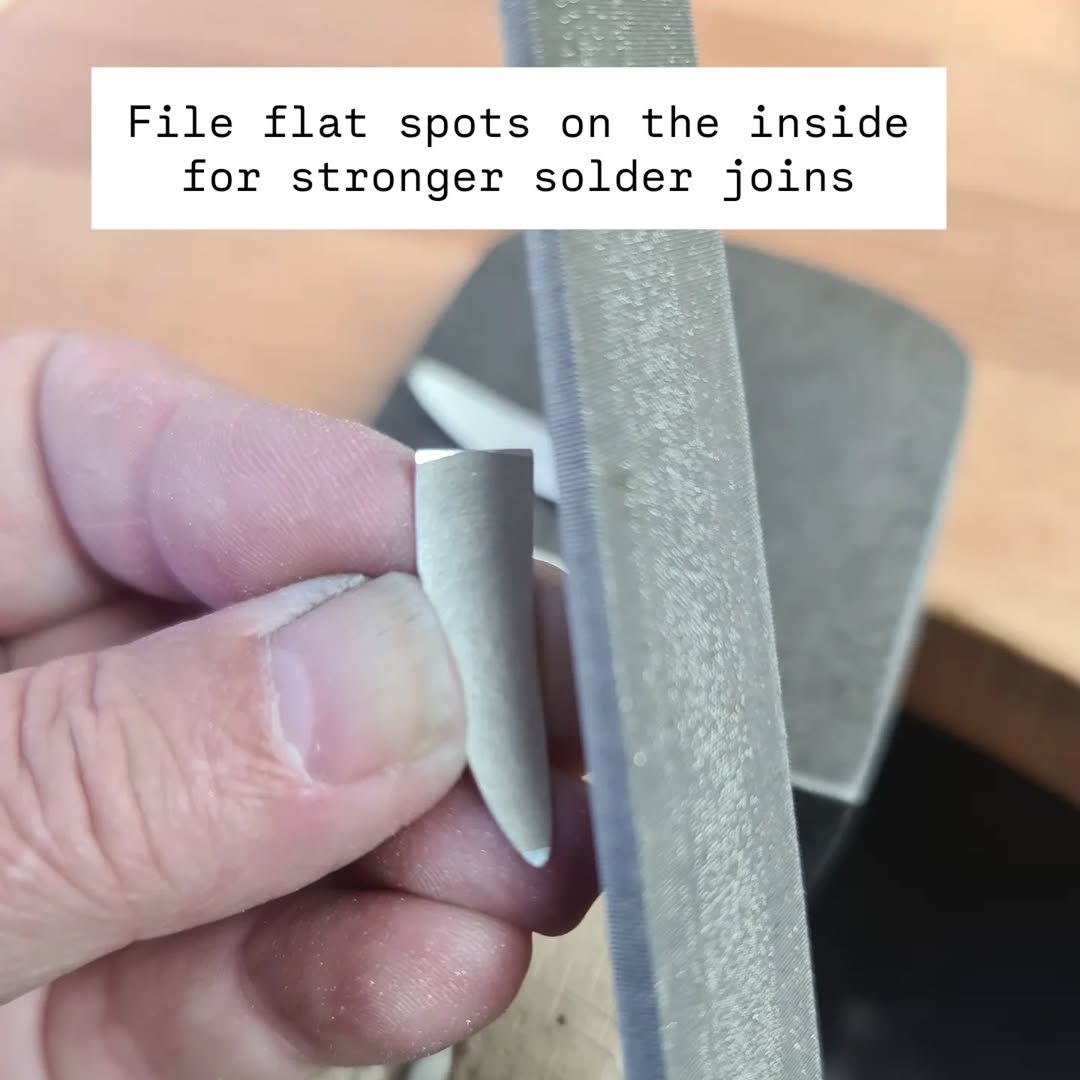

4. File flat across the back of each

silver shape. This will create small flat areas at the edges of the shapes.

These are the areas that will form the

solder join, and making them wider

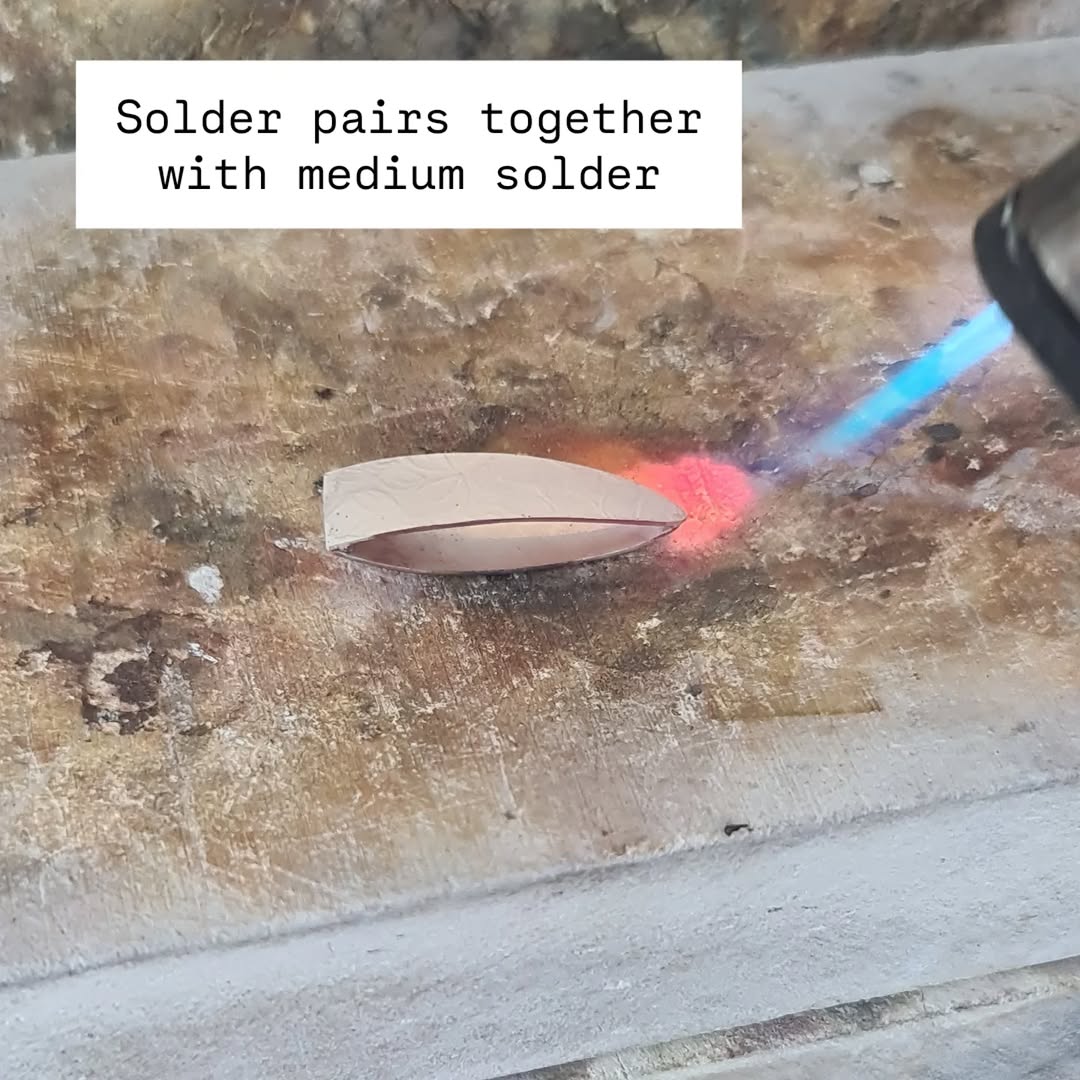

makes the joins stronger. | 5. Apply medium solder just inside

each solder join on one shape. I prefer solder paste for this job as

it's tackiness helps both silver and solder stay in place until the solder flows! Add a second shape on top. Sit the pair

on a solder brick, supporting with pennies

or similar if needed. Solder the pair

together. Repeat with the second pair

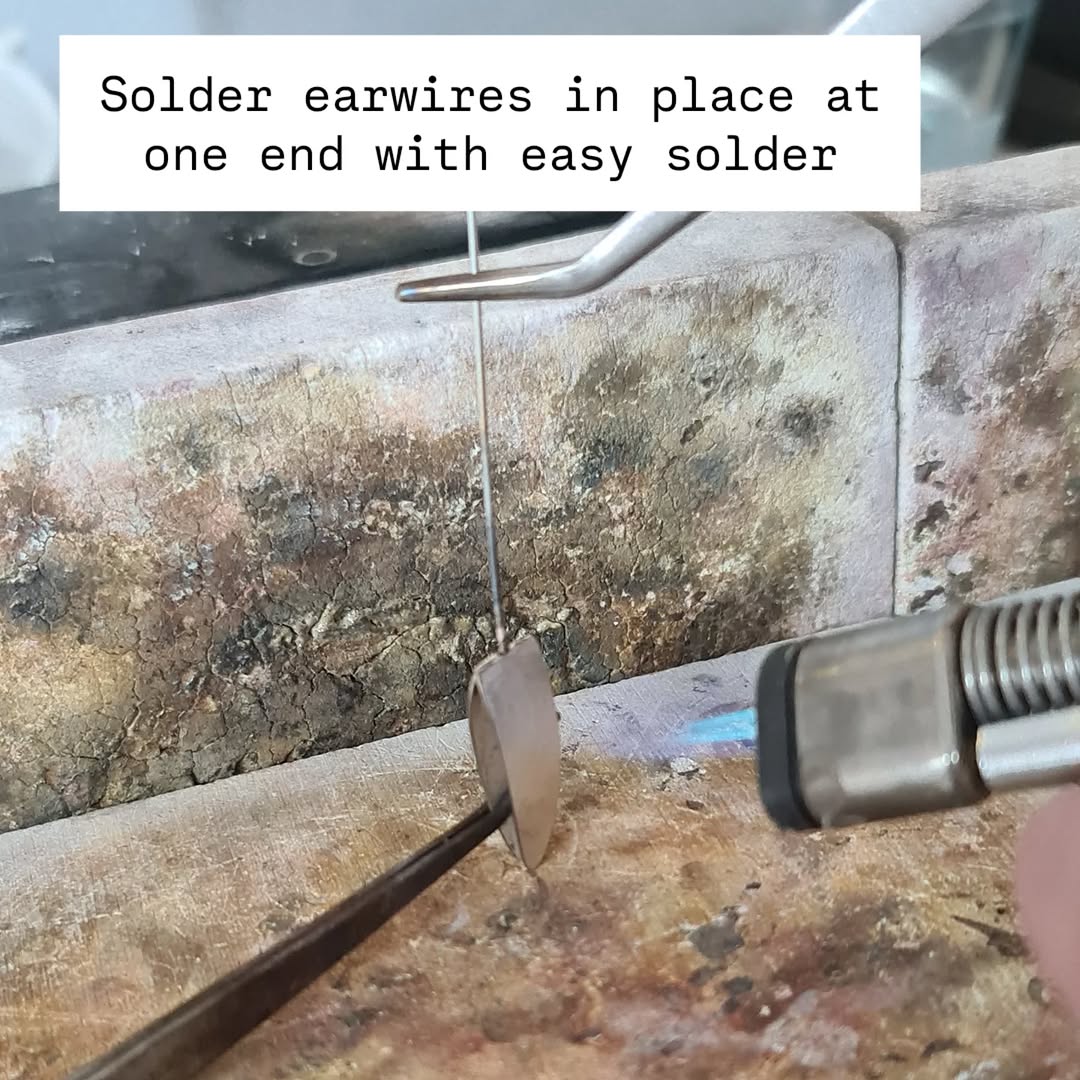

of shapes. Quench and pickle the shapes. | 6. Use a file or small ball burr to

create a small divot in the middle of one end of each of the newly soldered shapes. This creates seats for the earwires, making those solder joins stronger. Cut a suitable length of 0.8mm wire and

use easy solder to solder one end

in the divot created above. Repeat with the second earring. |

7. At this stage you can shape the earwire, polish your new earrings and wear them out to meet a friend for coffee - or you can get more creative! |

|  |  |

How about threading a pretty bead on

the earwire (before you bend it)

so that it sits on the silver shape? | Or perhaps add a tube set stone

or a bezel setting

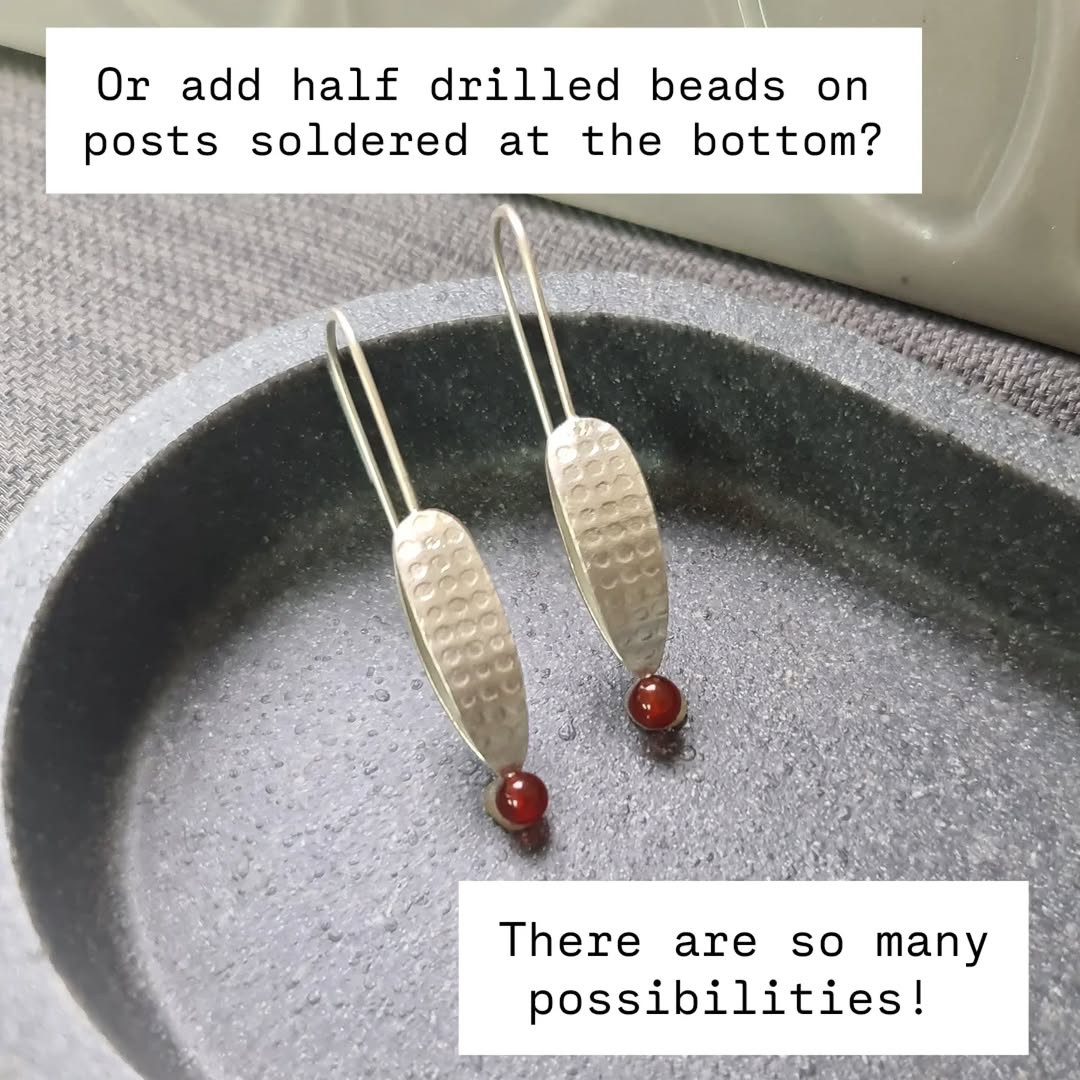

either above or below the silver? | Or maybe solder a post for a half-drilled pearl

or bead beneath the earring? |

If you're looking for more earrings inspiration

have a look at these classes...

|  |  |

Dotty Box Earrings | Petal Earrings | Spring Edition of the 52 earrings project |

Learn how to make hollow boxes - they're great for pendants too! | A quick project that uses silver left over from other projects. | The 52 earrings project resulted in 52 earring designs in one year. Enrol in just the Spring Edition, or go for the full year here. |

Categories: : earrings tutorial, jewellery tutorial, tool talk

Joanne Tinley

Tutor and Founder of The Jeweller's Bench

The Jeweller's Bench is run by Joanne Tinley. She has been making her own jewellery for as long as she can remember and left her first career as a school teacher to set up business as a jewellery designer and tutor nearly 20 years ago. She is

self-taught and like many people started with wire and beads. Learning how to solder, however, opened up a whole new world of jewellery making, one that she is keen to share!

Joanne Tinley

Joanne Tinley